INVEST IN TIME’S BEST INVENTION

We have reinvented the wheel to fix the cost, waste, and danger of rubber tires, a $280 billion market opportunity. Next stop: The Nasdaq.

Already +$6 million investments received.

Join over 4,000 investors and invest now.

Join over 4,000 investors and invest now.

As seen on:

PROBLEM

TIRES ARE COSTLY, DIRTY, AND DANGEROUS

Mining companies spend millions changing rubber tires on their vehicles every 6 to 9 months. In addition to the expense, rubber tires endanger workers and hurt the environment. After learning this, we've set out to revolutionize tires as a whole.

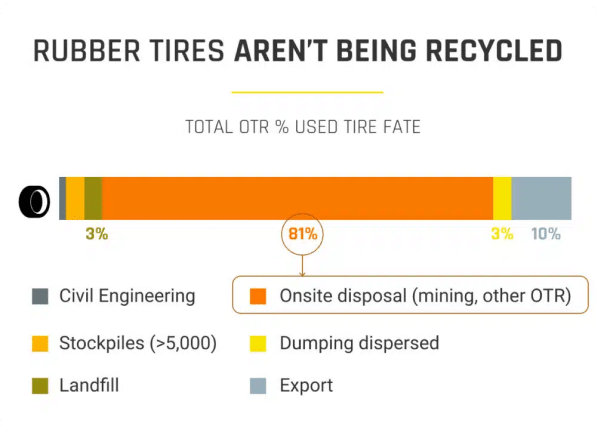

Pollution

28% of the ocean’s plastic consists of particles from rubber tires

Accidents

According to the NHTSA

35% of accidents caused

by cars happen due to bad tires

35% of accidents caused

by cars happen due to bad tires

Uneconomical

One 13,000 off-the-road (OTR) mining tire can cost over $75,000 and need to be replaced every 6 to 9 months

SOLUTION

A TIRE INNOVATION WITH TRACTION

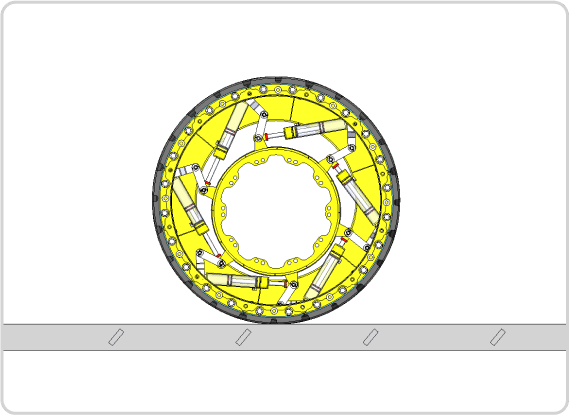

We succeeded where others failed, thanks to the nitrogen-filled cylinders that connect the outer steel drum with the inner hub. Energy is stored in the cylinders during braking and turned back into kinetic energy when rolling.

ECO-FRIENDLY

ASWs require minimal maintenance and are designed to last the lifetime of the vehicle. They’re also 100% recyclable.

SUPERIOR PERFORMANCE

Because of the reduced rolling resistance, the ASW burns less fuel.

SAFER

No overheating, no puncturing, less risk of trucks tilting, and better traction to reduce skidding.

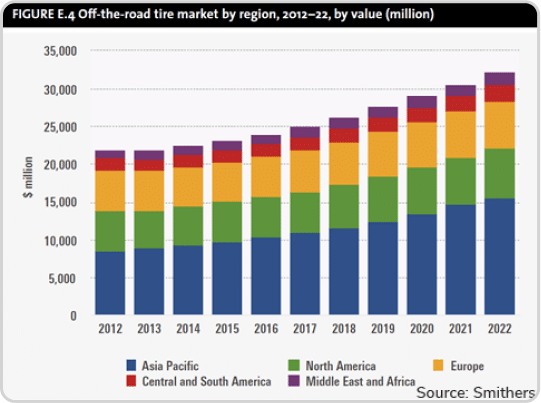

THE MARKET

GROWING DEMAND FOR A NEW WHEEL

The global tire market is expected to be worth $280 billion this year. We're starting in the mining market and plan to expand to the military market, automobile market, and beyond.

TRACTION

WE'VE MADE OVER $3M IN SALES

One 13,000 lb. OTR mining tire can cost over $75,000, and they typically only last 6 to 9 months. Our Air Suspension Wheel is more affordable, doesn’t shed rubber, and lasts the lifetime of the vehicle. That’s why we have $3M+ in sales so far.

$3M + in revenue so far

$1.5M in license deals

57 issued patents and over 50 patents pending

Three ongoing trials with mining companies

In conversation with +20 global mining firms

I want to know more about investing in GACW