RUBBER TIRES: THE POLLUTER YOU NEVER HEARD OF

Rubber tires are the polluter you have never thought of. Six million tonnes of rubber tire wear particles are released into the environment globally each year.

According to National Geographic a 2017 study by Pieter Jan Kole at The Open University of The Netherlands, published in the International Journal of Environmental Research and Public Health, it is estimated that tires account for as much as 10 percent of overall microplastic waste in the world’s oceans. A 2017 report by the International Union for Conservation of Nature put that number at 28 percent. (Source: https://www.nationalgeographic.com/environment/article/tires-unseen-plastic-polluter)

According to National Geographic a 2017 study by Pieter Jan Kole at The Open University of The Netherlands, published in the International Journal of Environmental Research and Public Health, it is estimated that tires account for as much as 10 percent of overall microplastic waste in the world’s oceans. A 2017 report by the International Union for Conservation of Nature put that number at 28 percent. (Source: https://www.nationalgeographic.com/environment/article/tires-unseen-plastic-polluter)

“Tire wear and tear is a stealthy source of microplastics in the environment,” wrote Kole and his co-authors. “But awareness is low and currently there is no alternative for tires.”

Today tires consist of about 19 percent natural rubber and 24 percent synthetic rubber, which is a plastic polymer. The rest is made up of metal and other compounds. Producing tires still has monumental environmental impacts, ranging from continued deforestation to the climate-harming fossil fuels used to make synthetic rubbers to the assembly process. Modern car tires require about 7 gallons of oil to make, while truck tires take 22 gallons.

Today tires consist of about 19 percent natural rubber and 24 percent synthetic rubber, which is a plastic polymer. The rest is made up of metal and other compounds. Producing tires still has monumental environmental impacts, ranging from continued deforestation to the climate-harming fossil fuels used to make synthetic rubbers to the assembly process. Modern car tires require about 7 gallons of oil to make, while truck tires take 22 gallons.

RECYLING OF RUBBER TIRES IS ALSO POLLUTIVE

Better understood is what happens to tires once they’ve run their course and need to be disposed of—“end of life,” as the tire manufacturing industry calls it.

The trajectory for used tires is, in many ways, positive. For example, the recycling of tire scraps into products such as playgrounds, sports fields, and building materials has increased dramatically over the years. The U.S. Tire Manufacturers Association (USTMA) says the re-use of tires has gone from 11 percent in 1990 to 81 percent in 2017.

The trajectory for used tires is, in many ways, positive. For example, the recycling of tire scraps into products such as playgrounds, sports fields, and building materials has increased dramatically over the years. The U.S. Tire Manufacturers Association (USTMA) says the re-use of tires has gone from 11 percent in 1990 to 81 percent in 2017.

But that number comes with a major caveat: It includes what is called “tire derived fuels” (TDF) —the burning of tires for energy.

According to Reto Gieré, an environmental scientist at the University of Pennsylvania, if tires are burned in facilities specifically designed for the task, it can be done fairly cleanly and is a decent way to recapture energy. But tires, he says, also contain high levels of potential pollutants such as zinc and chlorine, so if they’re burned in mixed-fuel facilities or without proper safeguards, he says, “we have a big mess.”

According to Reto Gieré, an environmental scientist at the University of Pennsylvania, if tires are burned in facilities specifically designed for the task, it can be done fairly cleanly and is a decent way to recapture energy. But tires, he says, also contain high levels of potential pollutants such as zinc and chlorine, so if they’re burned in mixed-fuel facilities or without proper safeguards, he says, “we have a big mess.”

THE ECO-FRIENDLY SOLUTION: AIR SUSPENSION WHEELS

ASWs do not produce rubber dust particles. The threaded shoes on the of the ASW outside can be fitted with biodegradable materials.

ASWs last as long as the vehicle itself and are 100% recyclable after their useful life.

ASWs last as long as the vehicle itself and are 100% recyclable after their useful life.

Additionally ASWs help reduce CO2 and NOX emissions because of fuel savings due to reduced rolling resistance.

DECREASE ECOLOGICAL FOOTPRINT OF MINING COMPANIES

An industry that uses and disposes rubber tires at an alarming rate, is the mining industry. With over 12,000 open-pit mines globally, the number of environmentally damaging tires disposed of each year is staggering.

One (1) giant rubber Off-The-Road (OTR) mining tire weighing 13,000 lbs contains 500 gallons of renewable blend oil, 4,000 lbs of carbon black, 2,000 lbs of steel, and over 3 million cu. ft. of synthetic gas (Titan International, June 2014). At the end of its useful life, the tire is disposed of on-site, repurposed or buried because recycling is often too expensive.

One (1) giant rubber Off-The-Road (OTR) mining tire weighing 13,000 lbs contains 500 gallons of renewable blend oil, 4,000 lbs of carbon black, 2,000 lbs of steel, and over 3 million cu. ft. of synthetic gas (Titan International, June 2014). At the end of its useful life, the tire is disposed of on-site, repurposed or buried because recycling is often too expensive.

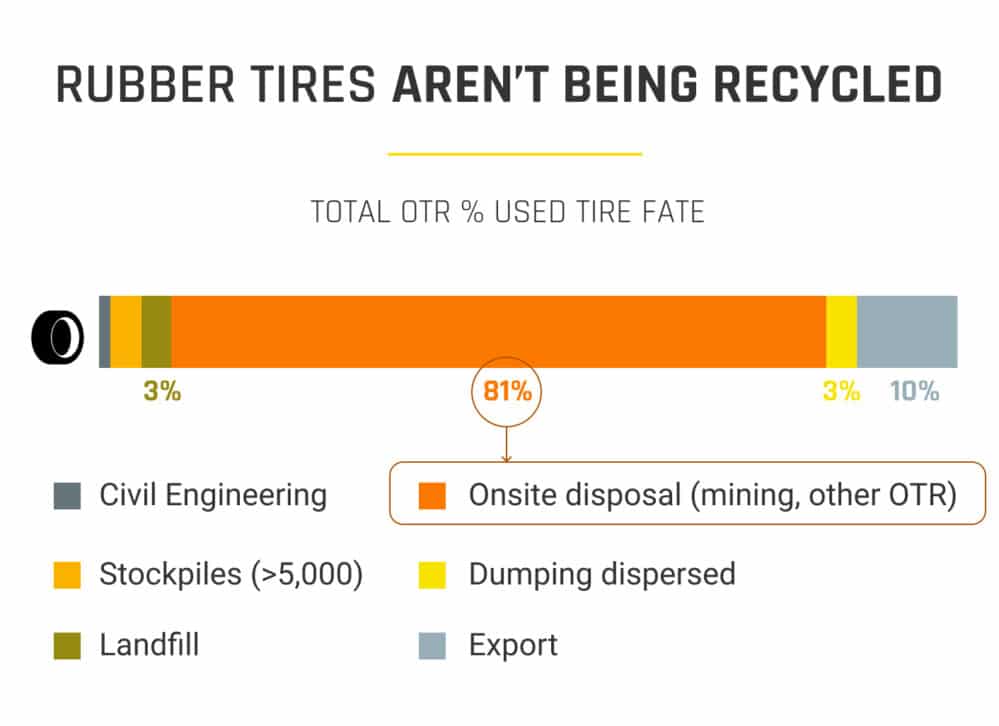

A report by Tyre Stewardship Australia produced in June 2020 found that 81% of OTR tires are disposed of onsite at the end of their lifetime (Source: https://www.tyrestewardship.org.au/wp-content/uploads/2020/06/Used-Tyres-Supply-Chain-and-Fate-Analysis.pdf)

The positive impact of ASW on the environment will be enormous. Mining trucks use up to twelve giant OTR tires each year. With each open pit mine operating several trucks, the amount of tires being buried or burned each year is staggering.

The positive impact of ASW on the environment will be enormous. Mining trucks use up to twelve giant OTR tires each year. With each open pit mine operating several trucks, the amount of tires being buried or burned each year is staggering.

Designed To Last As Long As The Vehicle

The Air Suspension Wheel changes an unreliable and unsafe consumable

into a predictable, safe, and eco-friendly capital asset.

into a predictable, safe, and eco-friendly capital asset.