AIR SUSPENSION WHEEL® REPLACES RIM, RUBBER TIRE, AND CHAIN

The Air Suspension Wheel® (ASW) is a ground-breaking, cost-saving, eco-friendly technology designed to replace the extremely pollutive rubber tire.

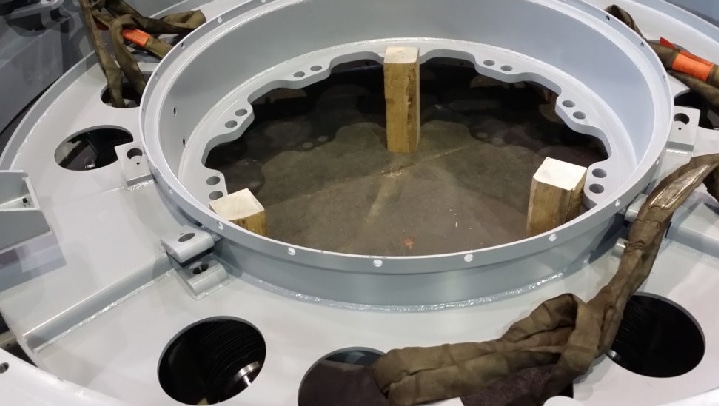

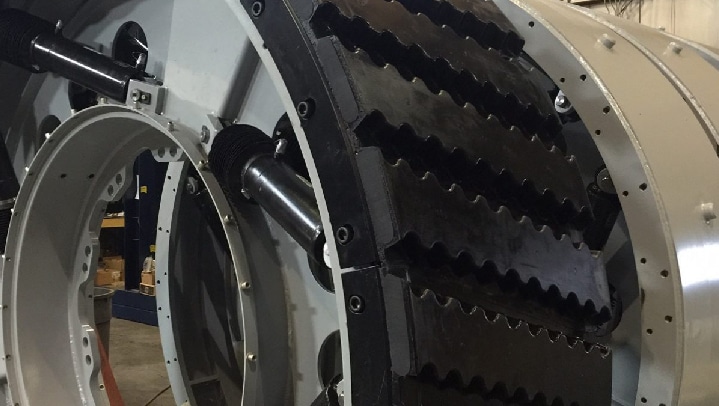

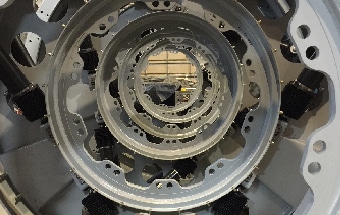

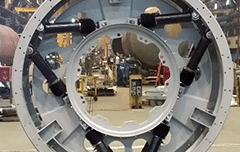

The Air Suspension Wheel® (ASW) replaces rim, rubber tire and chain. It combines an inner steel hub with an outer steel drum, which are connected by twelve nitrogen filled cylinders and six oil dampers, providing suspension.

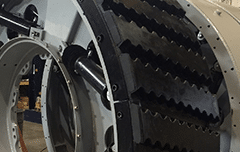

The outer drum can be fitted with bolt on customized polyurethane, steel or biodegradable treads, which can be individually replaced without removing the wheel.

The ASW is designed to replicate the tire size, load bearing capacity (or more if desired), and deflection. ASW’s overall weight is within the vehicle manufacturer’s guidelines.

HOW DOES IT WORK?

The ASW is a mechanical wheel primarily made of steel. The revolutionary design connects an inner steel hub with an outer steel drum through nitrogen filled cylinder, providing suspension. The outer drum is impact resistant and can fitted with biodegradable treads.

When braking, the energy is stored in the cylinders and is returned into kinetic energy when starting to roll again. And because of the reduced rolling resistance, the Air Suspension Wheel reduces energy consumption. This means less fuel burn and emissions or a significant extension of the battery range for electric vehicles.

INCREDIBLY STRONG

High Strain Ductile Steel

The inner wheel and outer tire structures are made from high-performance ductile steel which both have been welded and bolted together to withstand extreme conditions.

High Performance Nitrogen Cylinders

The nitrogen cylinders interconnecting the rim and drum have bidirectional movement and have a rated pressure of 2,500 PSI and a burst pressure of 10,000 PSI. The cylinders are hermetically sealed against mud, dust, rocks, and water. Additionally, the cylinders have internal lubrication and are sealed with high-performance elastomeric seals.

Solid Polyurethane or Steel Treaded Shoes

The solid treaded shoes are designed to last three to five times longer than OTR tires. They do not overheat and there is little deformation, moreover, there is no sensitivity to uneven tread wear. The ASWs can be outfitted with PU treaded shoes with a hardness range from Duro A55 to D85. Fire retardant treaded shoes are also available.

BETTER THAN RUBBER OTR TIRES IN EVERY ASPECT

HIGHER PAYLOAD CAPACITY

ASWs can be designed to handle higher payload capacity than rubber. Load differences also do not affect performance.

MORE LATERAL SIDE LOAD

ASWs have high lateral stability and only only have a marginal deformation. They are designed to cope with more lateral side load, making them more stable (less risk of truck tilting) and safer than rubber tires in sharp corners. They also have better traction and reduced skidding risk.

FUEL SAVINGS

ASWs can save fuel because the hub leads the wheel, the he cylinders store braking energy, and the smaller ground contact area of ASWs reduces rolling resistance.

NO OVERHEATING, NO EXPLOSIONS

ASWs cannot explode or overheat, making them safer for workers. With ASWs you do not longer need to deal with overheating, risk of fire and explosions, and tire changes in dangerous situations.

ELIMINATES DOWNTIME

The ASW eliminates precious downtime due to rubber tire failures or tires changes.

COST-EFFECTIVE

ASWs reduce costs because rubber OTR mining tires have to be replaced every six to nine months while ASWs last as long as the vehicle.

LESS MAINTENANCE

ASWs require minimal maintenance and are designed to last as long as the vehicle does. ASWs are self-aligning and self-balancing. The cylinders need a yearly check and the seals are designed to last three years. The bolt-on polyurethane treaded shoes are individually mounted and are easily replaced during a fuel stop.

CUSTOMIZABLE

ASWs can completely be customized based on your specific requirements for payload and strains. Larger than R63 wheels are possible. Thread hardness shore A55 up to D85. Fire retardant can be added to the threads.

SAFEST WHEEL IN THE MINING INDUSTRY

Designed To Last As Long As The Vehicle

The Air Suspension Wheel changes an unreliable and unsafe consumable

into a predictable, safe, and eco-friendly capital asset.

into a predictable, safe, and eco-friendly capital asset.